A Summary of the Process Behind the Introduction of 5S into Upper Cell Culture using the Six Sigma DMAIC Tool.

What is Lean Six Sigma?

LEAN is a business tool that allows for the identification and reduction of WASTE within a process, primarily through the optimization or elimination of NON-VALUE ADDED activities. This blog focuses on the introduction of a particular Lean tool, 5S, into a Biopharmaceutical Production environment. 5S is a business efficiency tool, originating from Japanese industry, that employs a systematic approach to reducing waste and streamlining a process.

SIX SIGMA is another business tool, often used in conjunction with Lean, which is concerned with the reduction of DEFECTS and VARIATION within a work process and also employs a systematic approach for sustainable problem solving. Both processes are very much DATA DRIVEN and when used used together allow for continuous improvement within a process with associated savings in cost, time and inefficiencies.

The driving force behind Six Sigma is the DMAIC improvement cycle.

Introduction: What is Our Problem?

- Our particular protein product, a monoclonal antibody, is manufactured using a Mammalian Cell Culture facility. Cells are inoculated into 100L vessels and grown on through 500L, 2,500L and 12,500L vessels. Cells are harvested and filtrated before transfer to the downstream process.

- Manufacturing has been ongoing in Upper Cell Culture since 2005.

- Drug Substance Proteins (DSP) is currently undertaking an expansion project to enable multi product manufacturing in 2017.

- This project will focus on improving current efficiency by removing waste from the production environment.

First task of the DEFINE phase is to compile a PROJECT CHARTER. This sets out the PROBLEM STATEMENT, the PROJECT DESCRIPTION and SCOPE as well as the support required. The project charter may also include a snapshot of the current BASELINE as well as any EXPECTED BENEFITS.

During an initial KAIZEN brainstorming workshop involving all stakeholders, a SIPOC diagram is often drawn up. SIPOC stands for Suppliers, Inputs, Process, Outputs and Customers. This, along with a FLOOR PLAN and a PROCESS FLOW MAP allow for the visualization of the process along with all inputs and outputs and helps to identify areas where improvements can be made.

SIPOC DIAGRAM:

When we are looking to introduce changes of any description into the working environment it is often advisable for reasons of project manageability, minimization of disruption and time constraints to isolate a particular part of the process and pilot the changes there. In this SIPOC diagram the set up of vessels for PT/SIP has been chosen (marked as Y1) as the pilot.

When we are looking to introduce changes of any description into the working environment it is often advisable for reasons of project manageability, minimization of disruption and time constraints to isolate a particular part of the process and pilot the changes there. In this SIPOC diagram the set up of vessels for PT/SIP has been chosen (marked as Y1) as the pilot.

FLOOR PLAN:

Giving an overview of how the floor space and process equipment is positioned in our work area.

PROCESS FLOW MAP:

Showing the connection between the various work processes.

VOICE OF the CUSTOMER (VOC) is a tool used to ascertain the requirements of either external or, as in this case, internal customers and often includes what are known as CRITICAL TO QUALITY (CTQ's) characteristics. These are key, measurable performance standards as defined by the customer.

VOC DIAGRAM:

Showing the main CTQ's, one of which, vessel set up time, being identified as the defined measurable improvement project.

The final task of the DEFINE phase is to ensure that we have a clearly defined PROJECT GOAL. In this case, the goal is to introduce 5S processes to initially reduce PT/SIP set up times on the seed vessels with a view to those same processes having a similar effect over the whole of Cell Culture.

The MEASURE phase of DMAIC involves the generation of data pertaining to current BASELINE process performance. This data can then be used in the future to determine the success or otherwise of any process changes made. The data capture in this case included among other things an overall visual record of the work area as seen in the pre-5S photographs shown below.

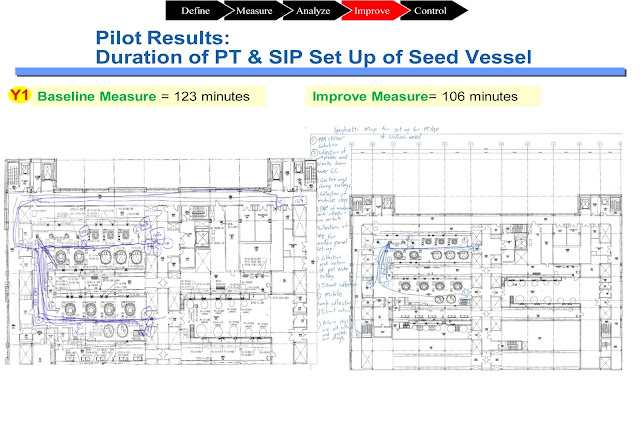

The particular process of interest, i.e PT/SIP set up time, was then measured across all areas for information purposes before the team focused on the pilot area for detailed study. A baseline set up measurement time (123 minutes) was recorded and the motion/movement of equipment, materials and operators were recorded visually with the aid of a hand drawn SPAGHETTI DIAGRAM.

MEASUREMENT OF OUR ISOLATED PROCESS ACROSS ALL SYSTEMS:

All systems measured for baseline PT/SIP set up times; Y1 being the area identified for more detailed measuring.

SPECIFIC MEASUREMENT OF ISOLATED PROCESS ON SYSTEM OF INTEREST:

An average PT/SIP set up time of 123 minutes was recorded for the Seed vessels and a visual record of movement and hand offs was recorded via a Spaghetti diagram.

The process was then further broken down into the individual tasks involved and each of these tasks was ranked according to a combination of length for completion and rate of occurrence. This data, along with the quantifying of the Spaghetti diagram data, allowed for prioritisation of the areas from which waste could be reduced.

When conducting analysis of our MEASURE data during our ANALYZE phase we have to be aware of what category each of our various tasks fits into. From a business perspective, all process tasks can be roughly divided into 3 areas; VALUE-ADD, where the product is being fundamentally changed at the request of the customer; BUSINESS-NON-VALUE-ADD tasks that are necessary for legal or regulatory reasons, and finally, NON-VALUE-ADD tasks which can often include wasteful activities and processes.

The aim of LEAN and its various tools is to optimize VA activities, minimize BNVA activities and ELIMINATE NVA WASTE.

The various different types of NVA activities can themselves be divided into 7 TYPES OF WASTE. These different areas of business waste can include things such as over-production, over-processing, transportation, motion, defects, inventories and waiting times and can be represented by the acronym TIMWOOD.

The waste of MOTION is concerned with any unnecessary or repetitive movements of the operator whilst they are performing their process tasks, eg de-gowning to retrieve a PBR .

Other types of waste identified included DEFECTS within the working environment.

Before embarking on any area improvements it is important to devise a clearly defined IMPROVEMENT PLAN. It is only now, during the IMPROVE phase that the techniques of 5S will begin to be implemented.

5S is a LEAN waste-reducing tool which is derived from the Japanese words of seiri, seiton, seiso, seiketsu and shitsuke. It can be roughly translated to the English terms of SORT, SET, SHINE, STANDARDIZE and SUSTAIN.

The first task in the SORT phase was to evaluate and remove all unwanted or unnecessary items from the work floor. This de-cluttering was performed using a RED TAG system where all items are red tagged for a length of time before removal, to ensure complete cross-shift agreement.

Various responses and fixes were then devised in response to identified wasteful tasks. Each of these improvements was advertised locally and ACTIVE COLLEAGUE INPUT and feedback was welcomed and encouraged before improvements were introduced.

Prior to the SET in order phase, a "place for everything, and everything in its place" mentality was fostered and a best practice PROPOSED FUTURE STATE MAP was agreed across all shifts. This map was colour coded with a fully mapped position for every work place item. Clearly defined local maps with easy-to-follow legends were also proposed.

During the SHINE phase, various improvements were then implemented throughout the workplace, always within the context of reducing the previously identified waste processes. These included specialised and dedicated holders for directly work-related items e.g set-up shadow carts, as well as various miscellaneous implements to aid in housekeeping. Several KANBAN systems were implemented to minimize inventory e.g O-rings and LEWA parts.

Optimal floor lay out was implemented, local signage was updated and other MOTION-reducing improvements occurred.

Simultaneous to the implementation of these improvements, a raft of best practice procedures were devised and clearly displayed to allow for the STANDARDIZE phase of 5S. These procedures included clear, step-by-step instructions on how to remove further unwanted items; the RED TAG PROCESS.

A procedure for continued measurable AUDITING with pre-determined (but open to amendment) audit questions and structures in place for recording and escalating audit actions.

Clearly displayed instructions on the REPLENISHMENT PROCESS, including lists of materials, suppliers and replenishment responsibilities.

A clearly defined process for TOOL/EQUIPMENT REPLENISHMENT and REPAIR.

A pre-populated timetable for both internal and external PROCESS CONFIRMATION duties to ensure ongoing compliance.

As well as a standardised procedure for the bedrock of any agile Production environment, that of the CONTINUOUS IMPROVEMENT LOOP. Complete with associated CI tracker.

All of these newly standardised procedures were then CLEARLY DISPLAYED in a central location on a dedicated 5S VISUAL BOARD to allow for embedding of the new work area ethos.

Measurable benefits were also posted to encourage colleague support and enthusiasm with our original pilot study showing a post-5S reduction of 16 minutes for the single set-up task. This equates to an overall time-for-task reduction of just under 14%.

Other Production benefits, particularly the generation of completed and proposed CI PROJECTS were documented and visually communicated.

In order to demonstrate that the introduction of 5S has and will result in real, tangible benefits we begin the CONTROL phase by communicating our pilot METRICS that resulted in a time saving of 14% at the first time of asking. The ongoing 5S process is by its nature cyclical and will lend itself to still further cumulative improvements.

Initially, as with any change in work practices, there can be a reticence to embrace the change and some low level resistance is to be expected. A change in ethos can be instigated within the workplace by conveying the benefits of NVA reductions and how these improved work practices can be of benefit to both the company and the employees in terms of the practicalities of doing their job. A PROJECT BENEFITS communication outlines tangible metric improvements as well as streamlined practices for ease of work flow.

Finally, the raft of standardised procedures drawn up in the IMPROVE phase are now live and subjected to regular ongoing PROCESS CONFIRMATION checks during the SUSTAIN phase of the 5S cycle. REPLENISHMENT cycles, AUDITING and STANDARD WORK processes are all examined during planned, regular 5S meetings and these in turn feed into the overall CI cycle.